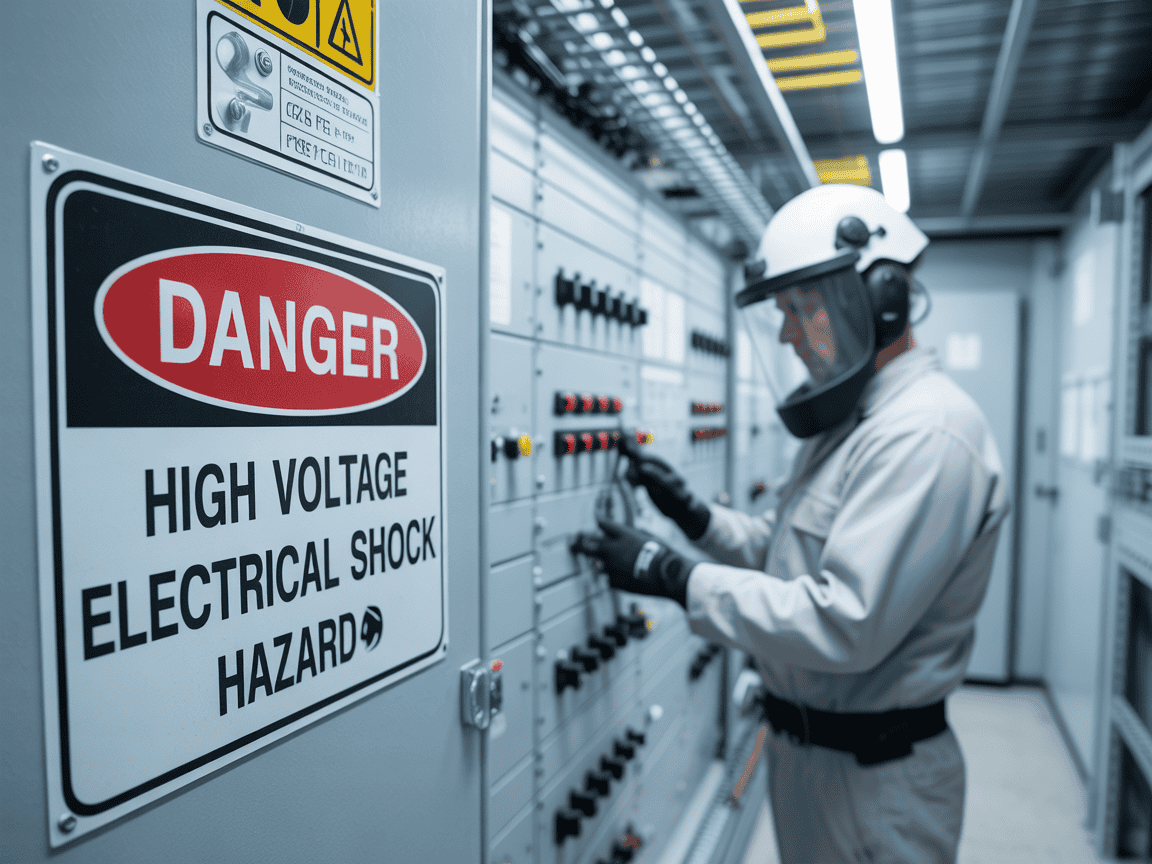

Why Lockout/Tagout is Critical in Modern Manufacturing

- Blog

Lockout/Tagout (LOTO) safety is critical for protecting technicians and maintenance teams in industrial environments. Yet, even experienced crews can fall into bad habits that put compliance and lives at risk.

The OSHA 1910.147 standard defines strict requirements for controlling hazardous energy during maintenance. Non-compliance can result in severe injuries, production downtime, or costly fines. Despite clear regulations, recurring mistakes in LOTO processes continue to threaten workplace safety.

ver 10% of serious accidents in industrial maintenance are linked to lockout/tagout failures.

Skipping the Verification Step

Many teams lock and tag equipment, but forget to test controls and verify zero energy states as required by OSHA 1910.147. This crucial step ensures all sources— electrical, pneumatic, hydraulic—are truly isolated.

Using Generic Tags or Locks

Locks and tags must be durable, standardized, and clearly identify the authorized employee. Unlabeled or generic devices create confusion and risk accidental energization.

Inadequate Employee Training

Industrial maintenance often involves teams. Failing to use group lock boxes or coordinate procedures can create dangerous gaps, especially during shift changes.

Related Posts