The Future of Lockout Tagout: From Paper to Intelligent Digital Control

Paper-based LOTO was never built for today’s complex facilities. Learn how governed digital workflows improve visibility, consistency, and audit readiness.

Understanding Electrical Hazards: Causes, Risks, and How to Prevent Them on Industrial Sites

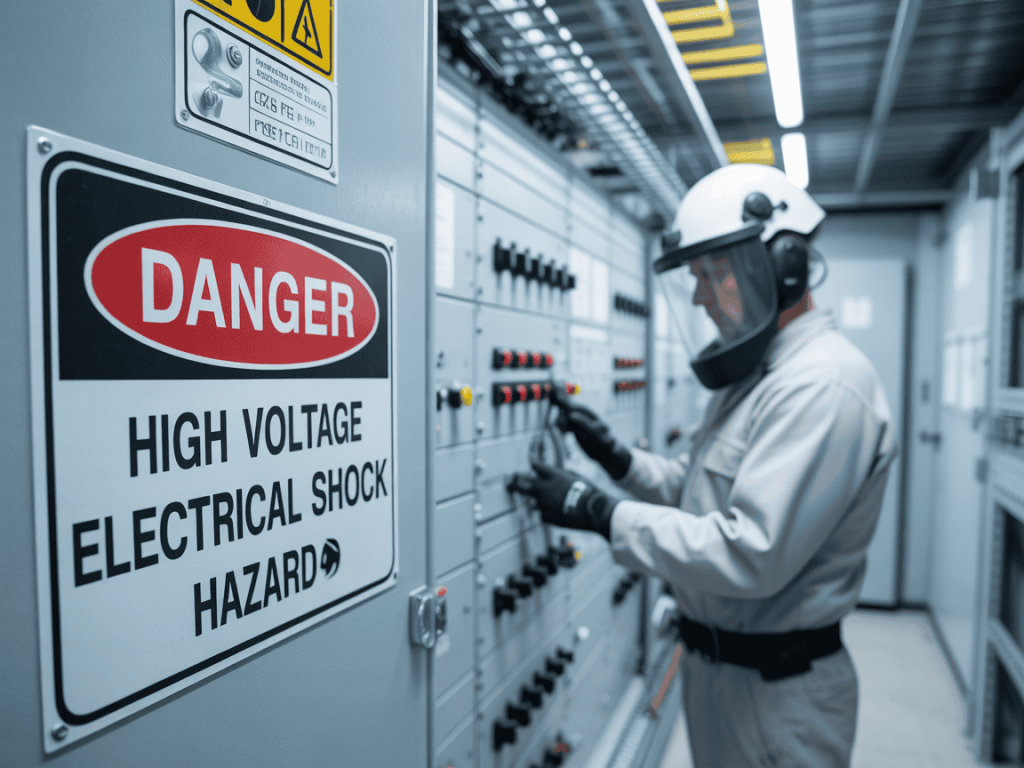

Electrical hazards refer to any situation where electric current can cause harm — through shock, burns, arc flash, or equipment failure. These dangers aren’t limited to direct contact with live wires; they also include indirect risks like exposed conductive parts or residual energy stored in equipment.

How to Prepare for a Third-Party Safety Audit: A Checklist for LOTO Compliance

Third-party safety audits are a reality for every high-risk worksite — whether from regulators, clients, or corporate HSE departments. And one of the most scrutinized areas during these audits is your Lockout/Tagout (LOTO) procedure.

Digital Transformation in Safety: Why Paper-Based LOTO Systems Are Becoming Obsolete

Industrial safety is evolving — and Lockout/Tagout (LOTO) procedures are no exception. While the principles of energy isolation remain unchanged, the tools we use to enforce them must keep up with the complexity of today’s work environments.

Lockout/Tagout (LOTO): The Critical Safety Procedure Many Sites Still Get Wrong

Lockout/Tagout (LOTO) is one of the most essential safety practices in high-risk industrial environments — yet it’s also one of the most frequently misunderstood, misapplied, or quietly bypassed. Whether you’re operating a data center, a refinery, or a power substation, LOTO isn’t just a box to tick; it’s your frontline defense against serious injury or fatality during equipment servicing.

Why Lockout/Tagout is Critical in Modern Manufacturing

Why Lockout/Tagout is Critical in Modern Manufacturing Lockout/Tagout (LOTO) safety is critical for protecting technicians and maintenance teams in industrial environments. Yet, even experienced crews can fall into bad habits that put compliance and lives at risk. The OSHA 1910.147 standard defines strict requirements for controlling hazardous energy during maintenance. Non-compliance can result in severe […]