Why Lockout/Tagout is Critical in Modern Manufacturing

- Blog

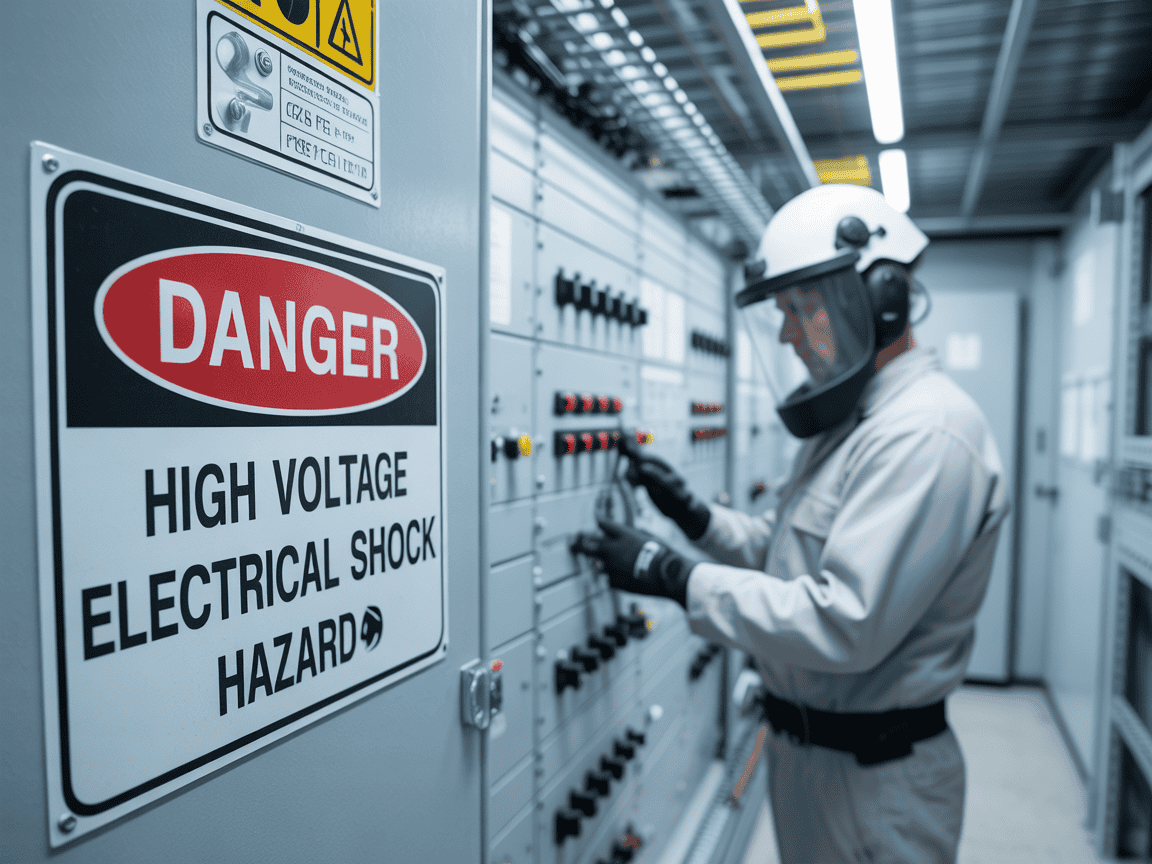

Lockout/Tagout (LOTO) safety is critical for protecting technicians and maintenance teams in industrial environments. Yet, even experienced crews can fall into bad habits that put compliance and lives at risk.

The OSHA 1910.147 standard defines strict requirements for controlling hazardous energy during maintenance. Non-compliance can result in severe injuries, production downtime, or costly fines. Despite clear regulations, recurring mistakes in LOTO processes continue to threaten workplace safety.

ver 10% of serious accidents in industrial maintenance are linked to lockout/tagout failures.

💡 Digital Transformation in Safety: Why Paper-Based LOTO Systems Are Becoming Obsolete

Industrial safety is evolving — and Lockout/Tagout (LOTO) procedures are no exception. While the principles of energy isolation remain unchanged, the tools we use to enforce them must keep up with the complexity of today’s work environments.

In a world of cloud-based asset tracking, smart PPE, and real-time risk dashboards, relying on paper forms and handwritten tags to protect lives is not only inefficient — it’s increasingly unacceptable.

🛠️ The Limits of Paper-Based LOTO

Traditional LOTO systems involve physical padlocks, handwritten isolation forms, printed procedures, and manual signatures. These methods are simple in theory but come with built-in challenges:

- Paper forms get lost or misfiled

- Steps are skipped under pressure

- Responsibility is unclear across teams

- There’s no live visibility for supervisors

- Audits are manual, slow, and error-prone

In complex environments like data centers, refineries, or semiconductor plants, even a single missed lock or outdated permit can lead to catastrophic incidents.

📊 The Real Cost of Staying Analog

Paper-based LOTO may seem cheaper — until it isn’t. The hidden costs include:

- Delays due to unclear isolation status

- Repeated site walkthroughs to confirm LOTO completion

- Miscommunication between trades and shifts

- Risk of failed inspections or non-compliance with client safety KPIs

- Difficulty proving due diligence in incident investigations

It’s no longer just a matter of safety — it’s about efficiency, liability, and business continuity.

🧠 What “Digital LOTO” Actually Means

Digitizing LOTO doesn’t mean replacing padlocks with apps. It means:

- Centralized workflow for isolation requests and approvals

- Digital lock records with time, location, and user data

- Interactive diagrams showing which points are isolated and by whom

- Real-time visibility for all stakeholders — from site leads to project managers

- Automated logs that are always audit-ready

The result is a closed-loop system that integrates safety, operations, and compliance into one smart platform.

🔐 LOTOControl: Built for the Field, Not the Office

LOTOControl was designed by professionals who understand site pressures — from commissioning deadlines to shutdown chaos.

With flexible deployment models (SaaS, client-hosted, or offline .EXE), it enables teams to:

- Go paperless without losing control

- Assign and verify roles with digital traceability

- Adapt LOTO workflows to suit every site or contract

- Improve audit readiness with zero additional admin work

🌍 Leading the Shift in Industrial Safety Culture

Across industries, digital transformation is no longer a buzzword — it’s a requirement.

Clients expect it. Auditors recommend it. Teams appreciate it.

By digitizing LOTO, companies send a clear signal:

“We take safety seriously, and we invest in doing it right.”

🔗 Conclusion

The time for paper-based LOTO systems is over.

If you’re looking to simplify energy isolation, reduce error, and future-proof your safety systems — now is the moment to act.

👉 Explore how LOTOControl helps industrial teams transition to a smarter, safer way of working.

[Request a demo]

Related Posts