The Future of Lockout Tagout: From Paper to Intelligent Digital Control

By admin_loto

/ February 26, 2026

Paper-based LOTO was never built for today’s complex facilities. Learn how governed digital workflows improve visibility, consistency, and audit readiness.

Read More

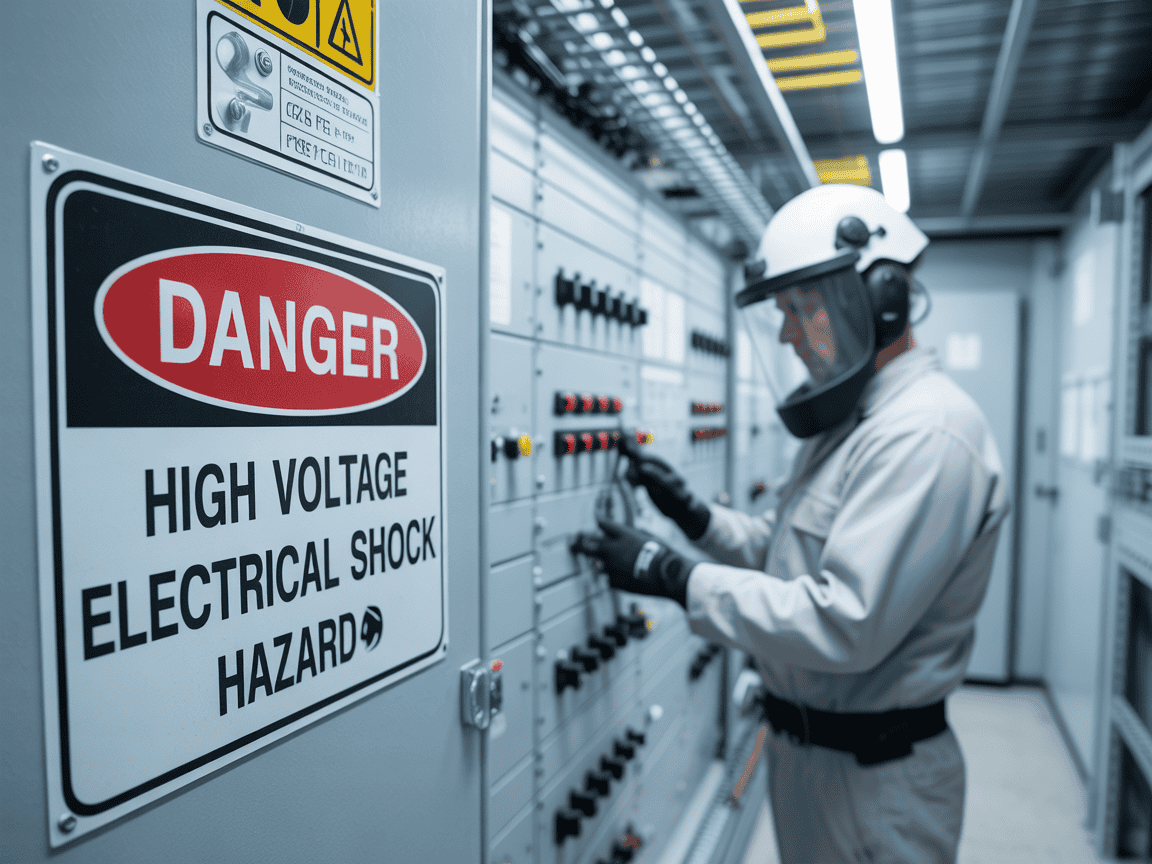

Understanding Electrical Hazards: Causes, Risks, and How to Prevent Them on Industrial Sites

By admin_loto

/ September 30, 2025

Electrical hazards refer to any situation where electric current can cause harm — through shock, burns, arc flash, or equipment failure. These dangers aren’t limited to direct contact with live wires; they also include indirect risks like exposed conductive parts or residual energy stored in equipment.

Read More

How to Prepare for a Third-Party Safety Audit: A Checklist for LOTO Compliance

By admin_loto

/ September 30, 2025

Third-party safety audits are a reality for every high-risk worksite — whether from regulators, clients, or corporate HSE departments. And one of the most scrutinized areas during these audits is your Lockout/Tagout (LOTO) procedure.

Read More

Digital Transformation in Safety: Why Paper-Based LOTO Systems Are Becoming Obsolete

By admin_loto

/ September 30, 2025

Industrial safety is evolving — and Lockout/Tagout (LOTO) procedures are no exception. While the principles of energy isolation remain unchanged, the tools we use to enforce them must keep up with the complexity of today’s work environments.

Read More

Lockout/Tagout (LOTO): The Critical Safety Procedure Many Sites Still Get Wrong

By admin_loto

/ September 30, 2025

Lockout/Tagout (LOTO) is one of the most essential safety practices in high-risk industrial environments — yet it’s also one of the most frequently misunderstood, misapplied, or quietly bypassed. Whether you’re operating a data center, a refinery, or a power substation, LOTO isn’t just a box to tick; it’s your frontline defense against serious injury or fatality during equipment servicing.

Read More

Download Brochures/Whitepapers Details

By admin_loto

/ July 31, 2025

Go Back to Download Brochures WhitepapersOSHA Control of Hazardous EnergyAs industrial environments grow more complex and highly automated, ensuring workplace safety remains a top priority. This whitepaper explores how organizations can modernize their Lockout/Tagout (LOTO) procedures by adopting digital solutions that enhance safety, compliance, and operational efficiency. Download Now Go Back to Download Brochures

Read More

Safety Standards References Details

By admin_loto

/ July 31, 2025

OSHA Control of Hazardous Energy U.S. regulation requiring procedures for controlling hazardous energy during the servicing and maintenance of machinery—commonly known as Lockout/Tagout (LOTO).CategoryLockout/Tagout (LOTO) | United States | Mandatory Safety StandardThe OSHA 1910.147 standard—commonly known as the Lockout/Tagout (LOTO) regulation—establishes minimum requirements for controlling hazardous energy during servicing and maintenance of machines and equipment. Its purpose is to prevent injuries caused by the unexpected startup or release of stored energy.This standard applies across a wide range of industrial settings, including manufacturing, utilities, oil and gas, construction, and data centers. It mandates that employers develop and enforce an energy control program, which includes written procedures, employee training, device labeling, and periodic audits.Key RequirementsEnergy control procedures: Step-by-step instructions for isolating and verifying hazardous energy.Lockout/tagout devices: Must be standardized, durable, and clearly identifiable.Authorized vs. affected employees: Clear role separation with required training.Annual audits: Required to evaluate program effectiveness and ensure compliance.Inadequate Employee TrainingIndustrial maintenance often involves teams. Failing to use group lock boxes or coordinate procedures can create dangerous gaps, especially during shift changes. Go Back to Safety Standards Reference Related Posts

Read More

Why Lockout/Tagout is Critical in Modern Manufacturing

By admin_loto

/ July 31, 2025

Why Lockout/Tagout is Critical in Modern Manufacturing Lockout/Tagout (LOTO) safety is critical for protecting technicians and maintenance teams in industrial environments. Yet, even experienced crews can fall into bad habits that put compliance and lives at risk.The OSHA 1910.147 standard defines strict requirements for controlling hazardous energy during maintenance. Non-compliance can result in severe injuries, production downtime, or costly fines. Despite clear regulations, recurring mistakes in LOTO processes continue to threaten workplace safety. ver 10% of serious accidents in industrial maintenance are linked to lockout/tagout failures.Skipping the Verification StepMany teams lock and tag equipment, but forget to test controls and verify zero energy states as required by OSHA 1910.147. This crucial step ensures all sources— electrical, pneumatic, hydraulic—are truly isolated.Using Generic Tags or LocksLocks and tags must be durable, standardized, and clearly identify the authorized employee. Unlabeled or generic devices create confusion and risk accidental energization.Inadequate Employee TrainingIndustrial maintenance often involves teams. Failing to use group lock boxes or coordinate procedures can create dangerous gaps, especially during shift changes. Go Back to Blog Related Posts

Read More

Whitepapers

OSHA Control of Hazardous Energy

As industrial environments grow more complex and highly automated, ensuring workplace safety remains a top priority. This whitepaper explores how organizations can modernize their Lockout/Tagout (LOTO) procedures by adopting digital solutions that enhance safety, compliance, and operational efficiency.