Understanding Electrical Hazards: Causes, Risks, and How to Prevent Them on Industrial Sites

- Blog

⚡ Understanding Electrical Hazards: Causes, Risks, and How to Prevent Them on Industrial Sites

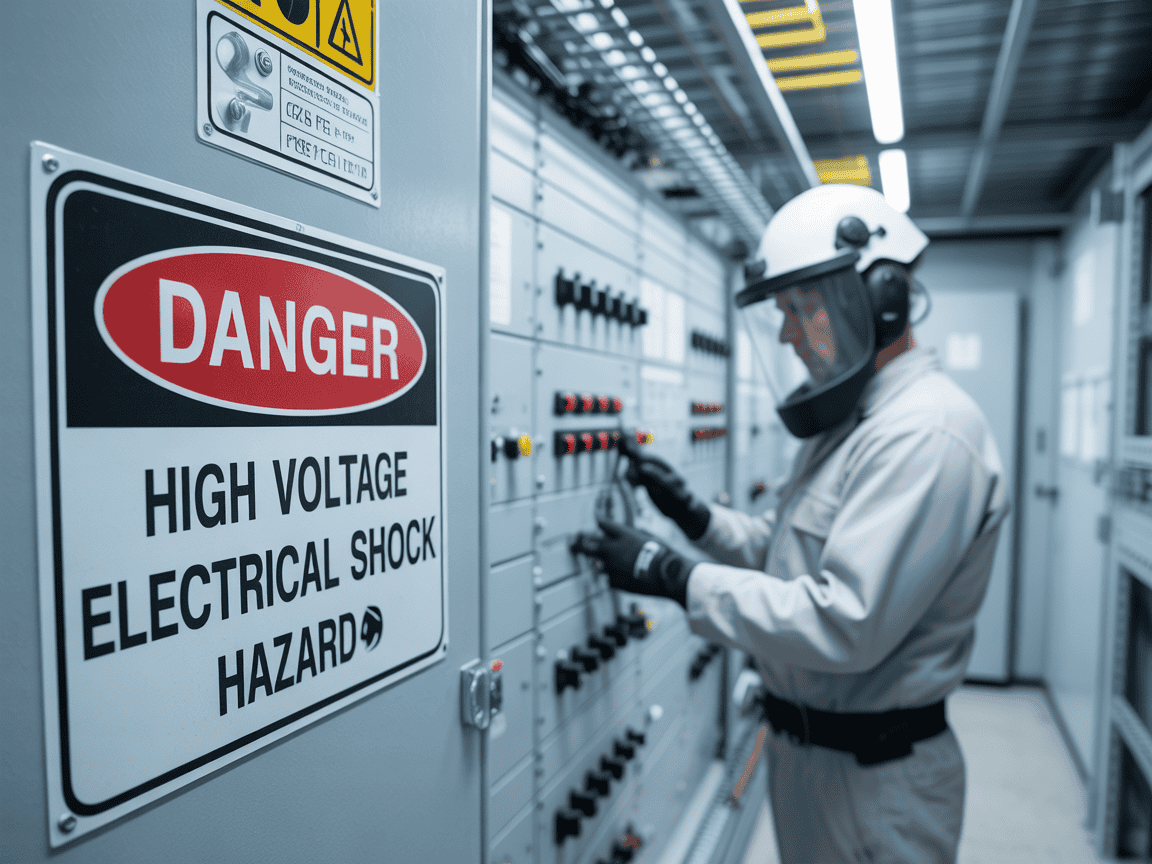

Electrical energy powers every industrial site — but unmanaged, it can also become one of its deadliest threats. Whether in a data center, oil & gas facility, or high-voltage substation, electrical hazards pose serious risks to both personnel and operations. Fortunately, most incidents are preventable with the right knowledge, training, and systems in place.

🔎 What Are Electrical Hazards?

Electrical hazards refer to any situation where electric current can cause harm — through shock, burns, arc flash, or equipment failure. These dangers aren’t limited to direct contact with live wires; they also include indirect risks like exposed conductive parts or residual energy stored in equipment.

In high-risk environments, even low-voltage systems can pose significant threats under certain conditions, especially if safety protocols aren’t rigorously followed.

⚠️ Common Causes of Electrical Accidents

Many electrical incidents stem from preventable issues:

- Poor insulation or faulty equipment

- Inadequate or absent energy isolation (LOTO) procedures

- Improper tool use or dropped objects

- Working on or near energized circuits without proper PPE

- Assuming a system is de-energized without verification

In industries like oil & gas and mission-critical facilities, such oversights can quickly escalate into life-threatening events — including arc flashes with temperatures exceeding 20,000°C, capable of causing severe burns and system-wide blackouts.

🧍♂️ The Human Impact — And the Organizational Cost

Electrical injuries range from minor shocks to permanent disability or fatality. Arc flash incidents, in particular, can lead to:

- Burns, nerve damage, or loss of limb

- Eye trauma or blindness from ultraviolet flash

- Hearing damage from pressure waves

- Lung injuries from inhaling toxic arc gases

Beyond human consequences, electrical incidents often result in:

- Equipment loss or prolonged downtime

- Disrupted operations and missed deadlines

- Regulatory penalties and reputational damage

✅ 4 Ways to Reduce Electrical Risk on Site

- Regular Equipment Inspections

Early detection of wear, corrosion, or poor connections is key to prevention.

- Proper Use of PPE and Barriers

Employees should never be exposed to live components without appropriate protection and training.

- Clear Work Permits and Procedures

Workflows must define when and how energy isolation is required — and who is authorized.

- Effective Lockout/Tagout (LOTO)

Perhaps the most critical tool in preventing unexpected energization during maintenance or handover.

🔐 LOTO: The Frontline of Electrical Safety

Lockout/Tagout (LOTO) is the standard for isolating energy sources before any work begins. But on real job sites, this system is often hindered by:

- Paper-based procedures that are prone to error

- Unclear responsibilities between trades

- Lack of real-time visibility on active isolations

- Audit gaps during inspections

That’s why industry leaders are turning to digital LOTO systems — to track, verify, and enforce energy isolation workflows with full accountability and speed.

🌐 The Safer Way Forward

Modern LOTO systems like LOTOControl are designed for complex industrial operations, offering:

- Real-time dashboards for isolation status

- Digital approvals and user traceability

- Structured procedures aligned with your organization’s safety protocols

By digitizing Lockout/Tagout, teams reduce human error, accelerate compliance, and enhance safety culture — without compromising performance or flexibility.

🧭 Final Thoughts

Electrical hazards may always be present — but preventable accidents shouldn’t be.

If your team relies on paper LOTO forms or fragmented workflows, now is the time to explore a smarter alternative.

👉 Discover how LOTOControl brings simplicity, traceability, and control to the heart of energy isolation.

[Request a demo]

Related Posts